Introducing Chill-Max Brand Secondary Regulator Panel Kits

Upgrades & New Features

A functional keg cooler is an integral part of any F&B establishment, no matter the size of their beverage program. A properly designed and constructed refrigeration system and keg storage room will help maintain smooth day-to-day operations, allowing employees to navigate the space properly, giving technicians easy access, and improving overall appeal.

Towards the goal of improving panel and fridge functionality, Canadian Beverage Supply & Chill-Max Beverage Solutions have introduced their innovative Chill-Max brand secondary regulator panel system, incorporating a number of beneficial, upgraded features.

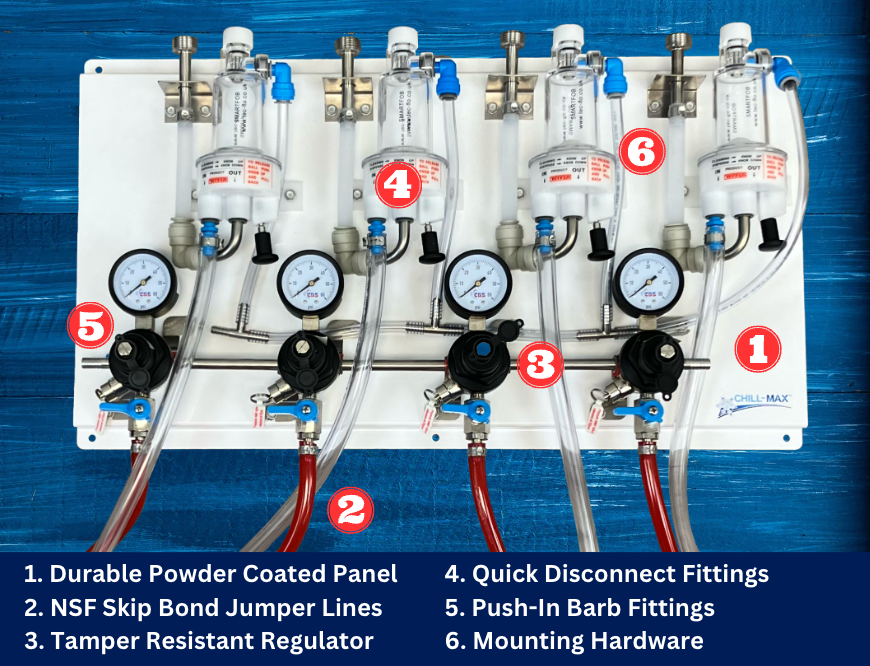

These new Chill-Max brand secondary regulator panel kits are offered in several configurations that will suit any beverage system design. Our designs start with a clean, crisp, and easily maintained smooth white powder coat finish, and are finished off with the highest quality components the beverage dispense industry has to offer. The panels are loaded with convenient features including quick-disconnect fittings, a tamper-resistant regulator, skip bond jumper line sets, and more.

Continue reading to learn more about the features of our new Chill-Max brand secondary regulator panel kits.

Highlighted Features

While the new secondary regulator panels include a variety of new features, we would like to outline some that we believe are especially unique and valuable.

1. Durable Powder Coated Panel

Unlike comparable units, our panel features a durable powder coating. In a standard white, this coating is easy to clean, scratch-resistant, and provides a streamlined appearance. The coating provides a stark contrast to the fittings and tubing, allowing the panel to stand out from its surroundings. Additionally, you are able to brand any of our panel kits with your company logo and colours. This panel is a striking addition to the keg cooler, showcasing your brand and work.

2. NSF Skip Bond Jumper Line Sets

This feature enhances your space both functionally and aesthetically. The gas and beer tubes are fused together and gapped every 6 inches, creating a uniformity between the beer and gas lines, and allowing for a neat and clean installation. Additionally, you will no longer require cable ties nor will you encounter any “shark bites,” to keep the beer and gas lines together, improving organization and ease of use within the fridge. Unlike traditional tying methods, the Skip Bond Jumper Lines’ fused connections will not change the shape of the tubes, allowing for smooth flow and increased longevity.

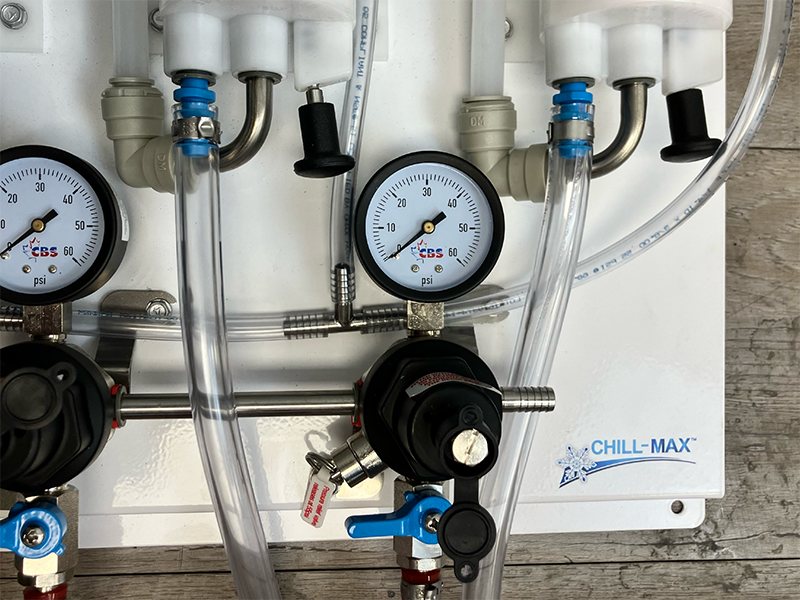

3. Tamper Resistant Regulator

The Tamper Resistant Regulator allows you to ensure that your pressure is always maintained at the proper level, avoiding unnecessary adjustments. A secure tab is located on the adjustment screw, allowing only authorized individuals access to adjust the pressure. As even a small pressure adjustment can greatly affect the way your beverage pours, this feature can help improve the quality of your product between maintenance appointments.

Stainless Steel Fittings

Another major feature of the new panels is that brass fittings have been eliminated, replaced with 304SS and plastic fittings. This includes wall brackets, joiner tubes, inlet/outlet fittings, tailpieces, beer nuts, and more.

Stainless Steel is a preferred material for food and beverage equipment due to its longevity, corrosion resistance, and purity. It is often even used in marine applications, where it is constantly exposed to degrading conditions. Its use for beer fittings will help improve your system’s performance and provide an increased lifespan.

4. Quick Disconnect Fittings

The Quick-Disconnect fitting is unique to CBS panels, and provides benefits to both the flexibility and durability of your system. Score marks on the fitting make it less likely to be pulled apart under pressure, as teeth within the cartridge can “bite” into it. Additionally, it provides flexibility on which John Guest fitting and tubing size you choose to use. Increased options allow you to further customize your setup based on your needs, without sacrificing in another area.

5. Push-in Barb Fittings

304SS push-in tubes are used to connect the inlet and outlet on each regulator, with push-in barb fittings used on the gas inlet and outlet. This feature allows you to quickly change out fittings or create a ganged regulator when required.

6. Mounting Hardware

Finally, the mounting hardware included with the panel allows for easy installation and adjustment. Using stainless steel self-tapping screws to fasten the components to the panel, this feature introduces additional flexibility and ease-of-use. Unlike on a traditional panel, there is no nut required to fasten the components. As such, you will no longer need to access the back of the panel, and will not need to remove the panel from the wall or use a long wrench to make adjustments or replace parts. Further, our use of stainless steel means the mounting hardware is corrosion resistant and easy to remove, no matter the conditions.

These are only a few of the features included on CBS’ new coupler panels. To learn more about our Chill-Max brand secondary regulator panels, please contact our team by calling 1-888-303-7707.